spine implants made in china

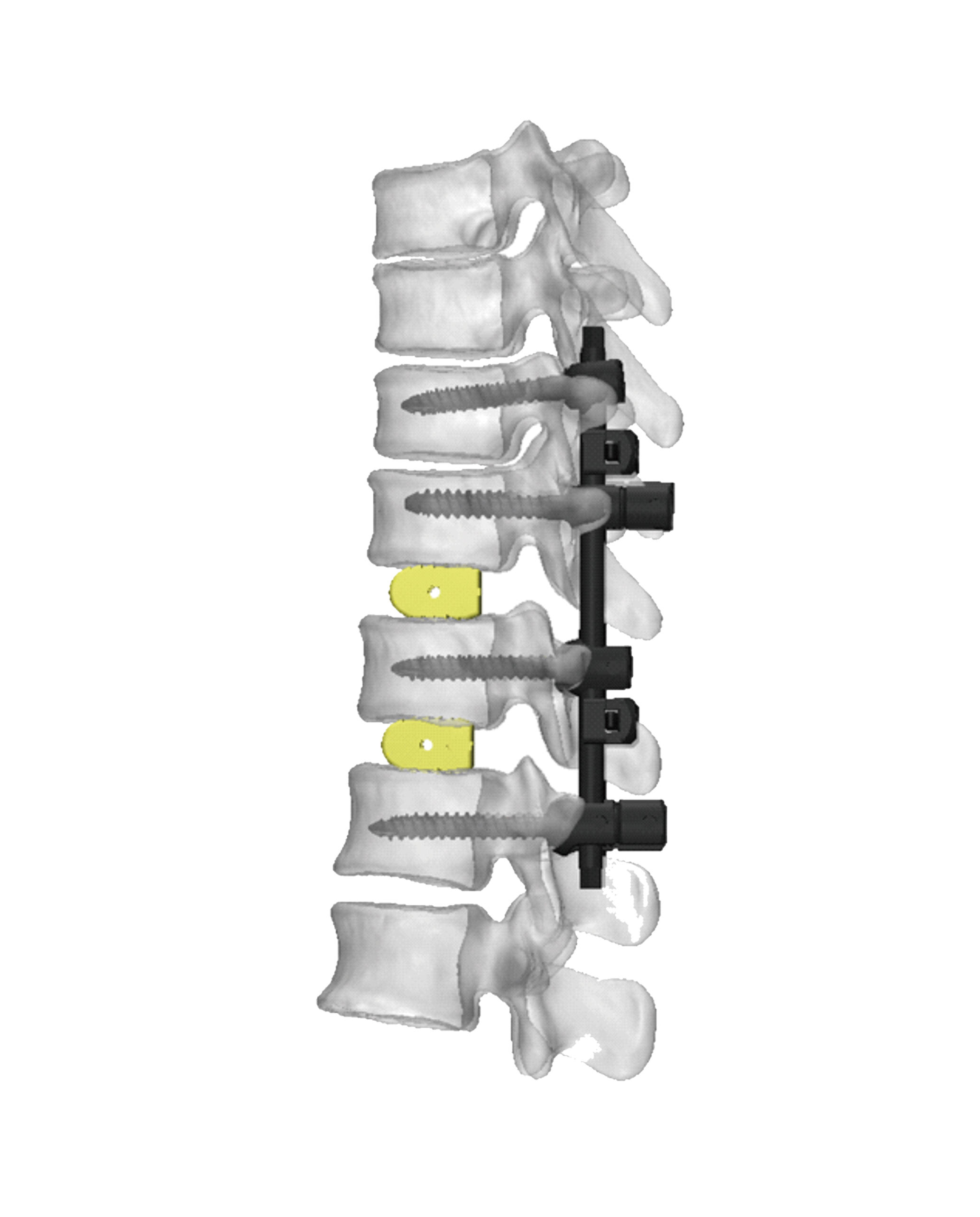

Spine implants made in China represent a significant advancement in medical device manufacturing, combining cutting-edge technology with cost-effective production. These implants encompass a comprehensive range of solutions, including pedicle screws, spinal cages, plates, and artificial discs, all manufactured under strict quality control measures. The implants utilize medical-grade materials such as titanium alloys and PEEK (polyetheretherketone), ensuring both durability and biocompatibility. Chinese manufacturers employ state-of-the-art manufacturing processes, including precision CNC machining and 3D printing technologies, to create implants that meet international standards. These devices are designed to address various spinal conditions, from degenerative disc disease to traumatic injuries, providing essential support for spinal fusion procedures and vertebral stabilization. The manufacturing facilities maintain ISO 13485 certification and comply with FDA requirements, ensuring consistent quality and reliability. The implants undergo rigorous testing protocols, including mechanical stress testing, biocompatibility assessments, and sterilization validation, guaranteeing safety and efficacy for patient use.