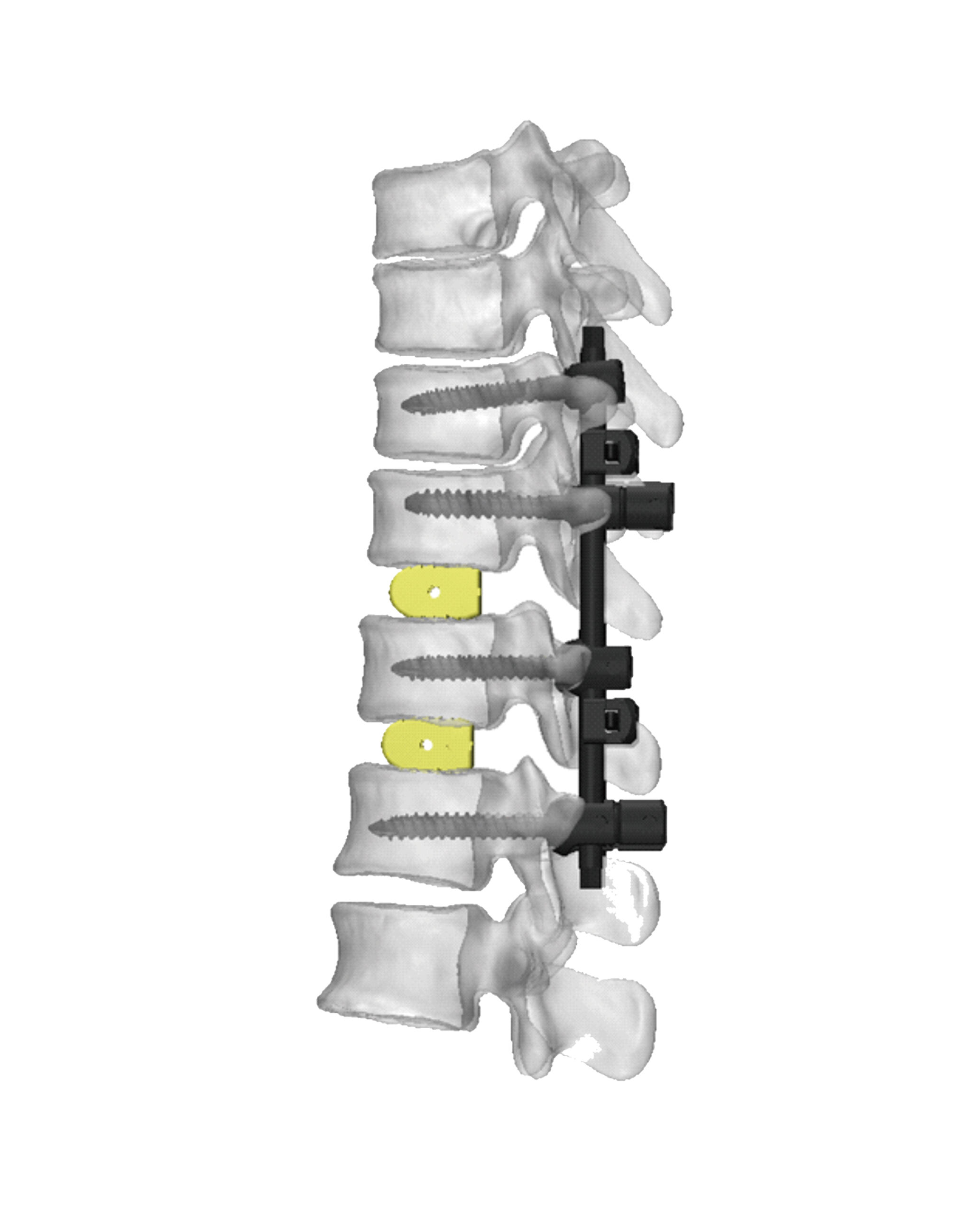

customized spine implants

Customized spine implants represent a revolutionary advancement in medical technology, offering tailored solutions for patients requiring spinal surgery. These innovative devices are designed and manufactured using cutting-edge 3D printing technology and advanced imaging techniques to create patient-specific implants that perfectly match individual anatomy. The implants are crafted from biocompatible materials such as titanium alloys or PEEK, ensuring optimal integration with the patient's natural bone structure. The customization process begins with detailed CT or MRI scans, which are converted into precise 3D models. These models serve as the foundation for designing implants that account for unique anatomical variations, deformities, and specific pathological conditions. The technology enables surgeons to address complex spinal conditions with unprecedented accuracy, including degenerative disc disease, spinal stenosis, and severe spinal deformities. The implants incorporate specialized surface textures and porosity levels that promote bone ingrowth and long-term stability. This personalized approach significantly improves surgical outcomes, reduces operation time, and enhances post-operative recovery. The system includes comprehensive pre-operative planning tools that allow surgeons to visualize and optimize implant placement before entering the operating room.