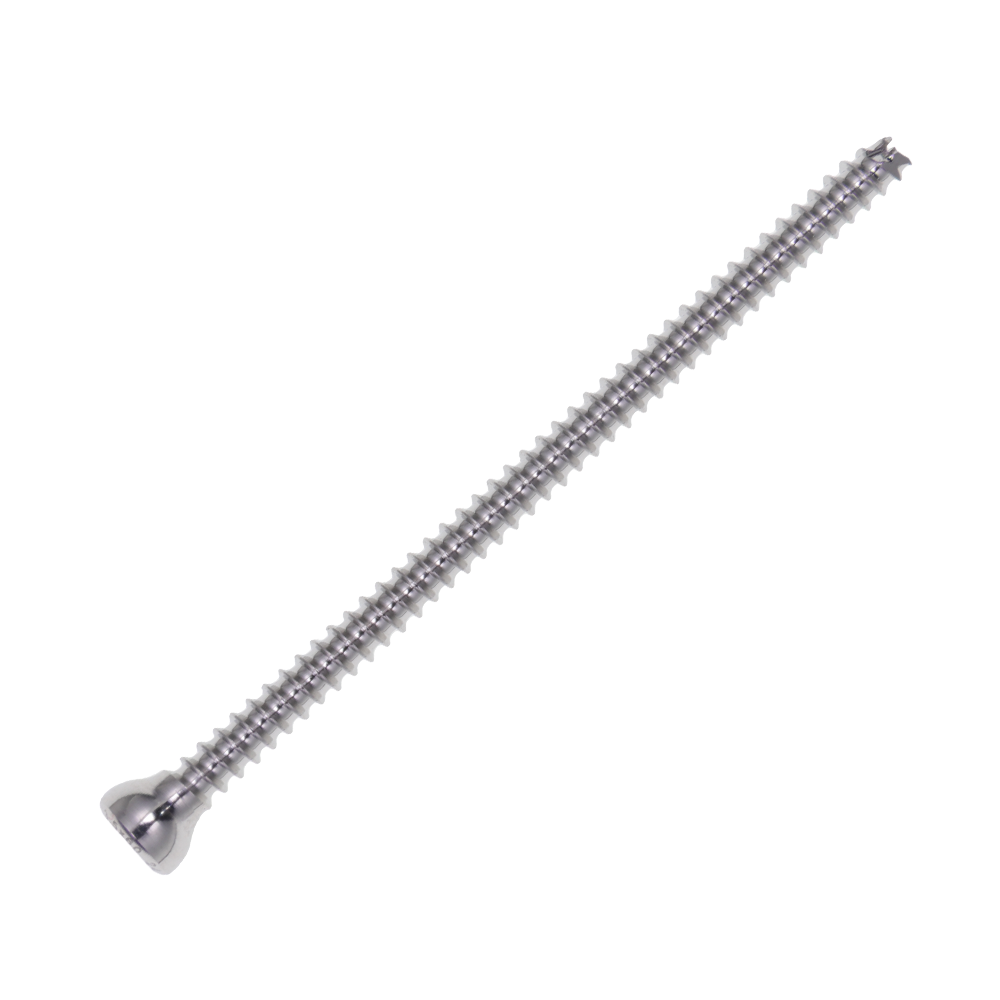

screw used in orthopaedics

Orthopaedic screws represent essential components in modern surgical procedures, serving as crucial fixation devices in bone reconstruction and repair. These precision-engineered implants are designed to provide stable internal fixation, facilitate bone healing, and restore anatomical alignment. The screws are manufactured from biocompatible materials, primarily titanium alloys or stainless steel, ensuring optimal tissue compatibility and long-term stability. They feature specialized threading patterns that enhance purchase in bone tissue while minimizing trauma during insertion. The design typically includes a threaded shaft, head, and core diameter optimized for specific anatomical locations and surgical requirements. Contemporary orthopaedic screws incorporate advanced surface treatments to promote osseointegration and reduce infection risks. They come in various configurations, including cancellous, cortical, and cannulated designs, each serving specific surgical needs. The technology behind these screws continues to evolve, with recent innovations focusing on improved biomechanical properties and enhanced surgical precision through computer-assisted design and manufacturing processes.