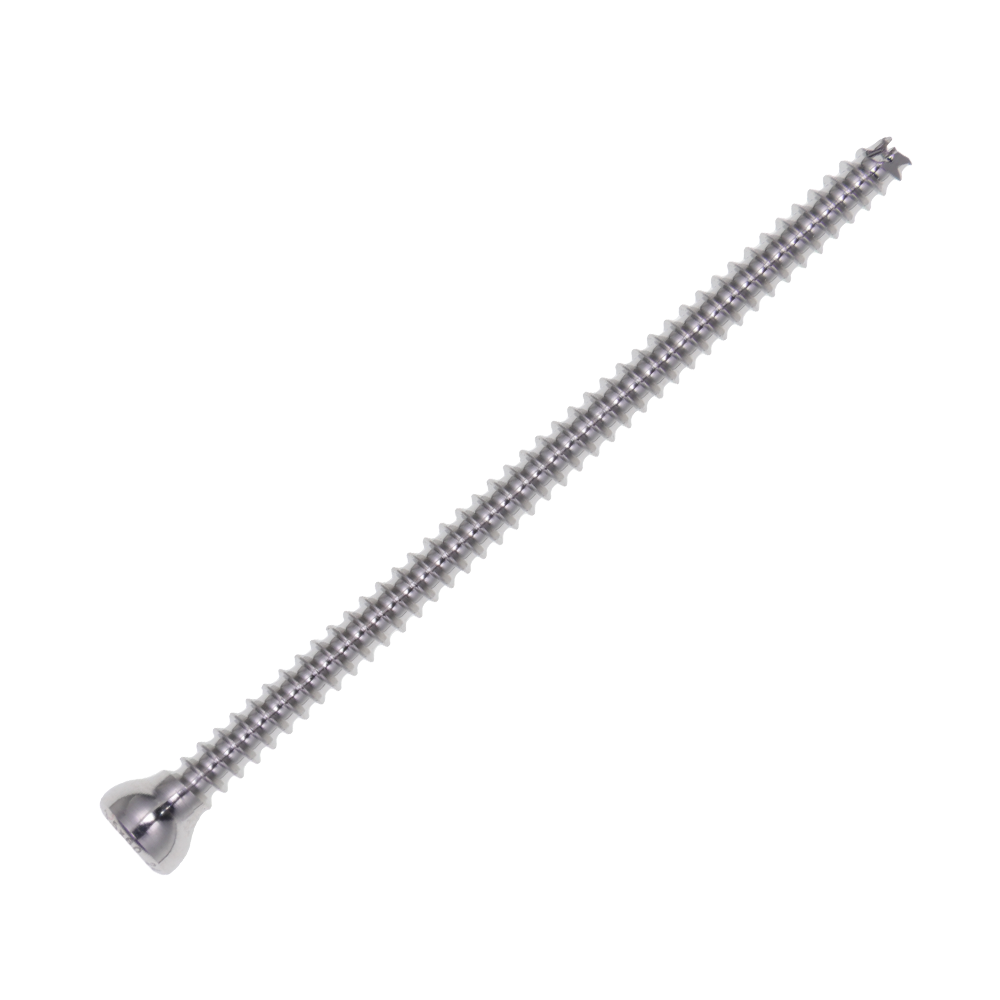

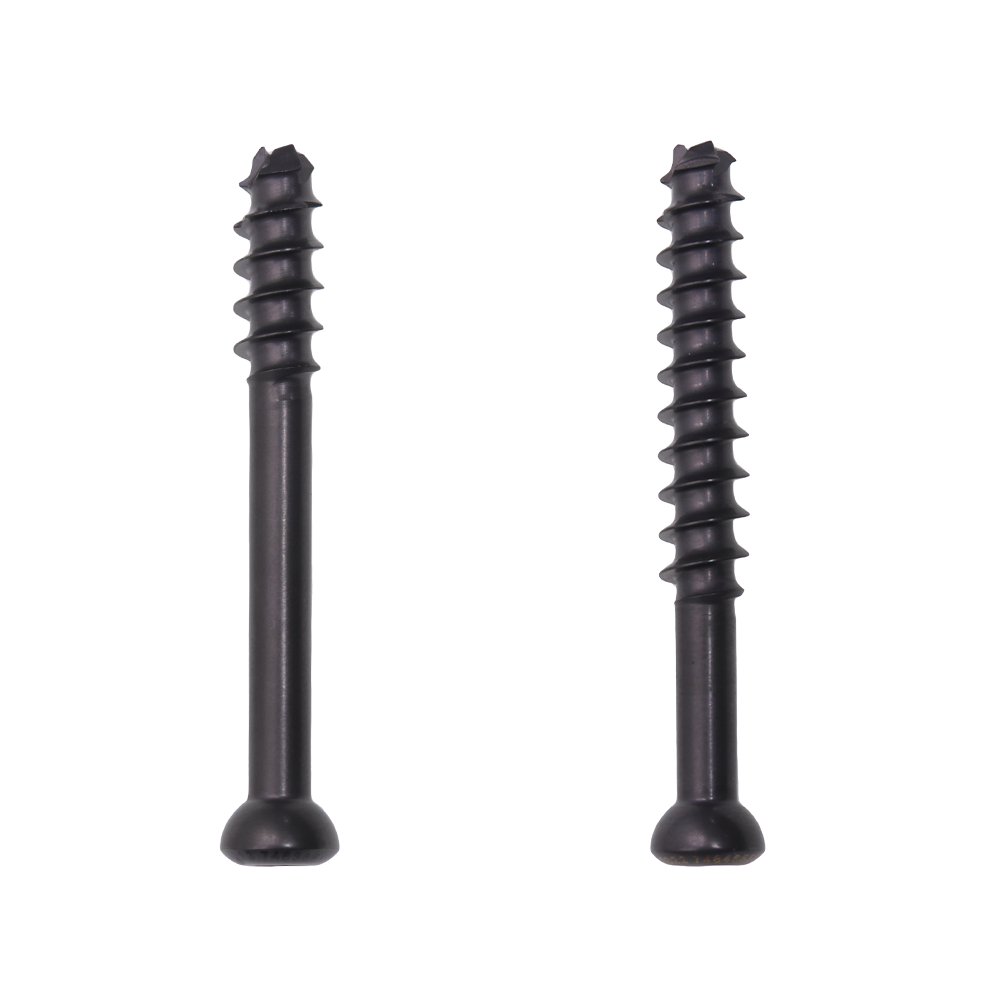

orthopedic bone screw

An orthopedic bone screw represents a crucial advancement in modern surgical technology, serving as a fundamental component in skeletal fixation and reconstruction procedures. These precision-engineered implants are designed to provide stable internal fixation of fractured bones, facilitate proper healing, and restore anatomical alignment. Manufactured from biocompatible materials such as titanium alloys or surgical-grade stainless steel, these screws feature specialized threading patterns that ensure optimal purchase in both cortical and cancellous bone tissues. The design incorporates various head types, thread configurations, and core diameters to address specific surgical requirements and anatomical locations. Modern orthopedic bone screws often feature self-tapping capabilities, reducing the need for pre-drilling and minimizing surgical time. They are available in multiple sizes and lengths, allowing surgeons to select the most appropriate option for each unique case. Advanced surface treatments enhance osseointegration and reduce the risk of infection, while innovative head designs facilitate secure attachment to plates or other fixation devices. These screws play an essential role in various orthopedic procedures, from simple fracture repairs to complex reconstructive surgeries, making them indispensable tools in contemporary orthopedic practice.