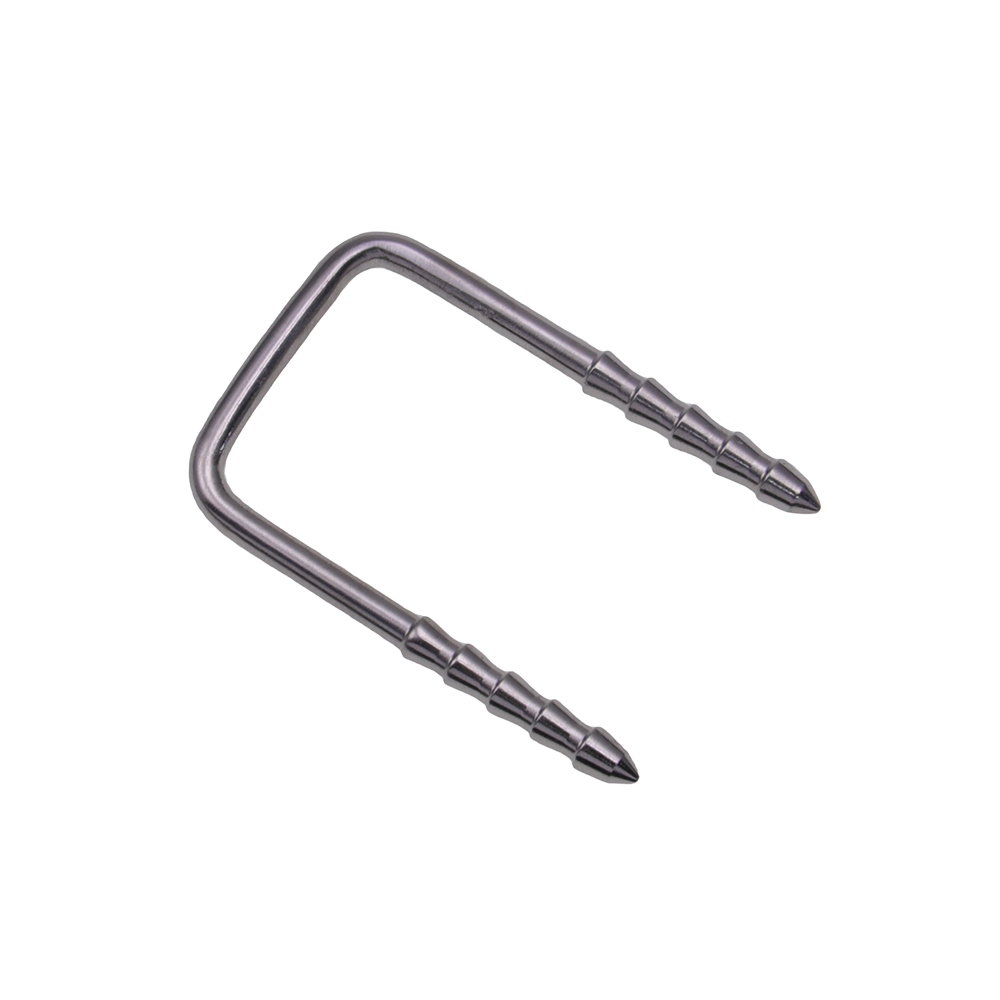

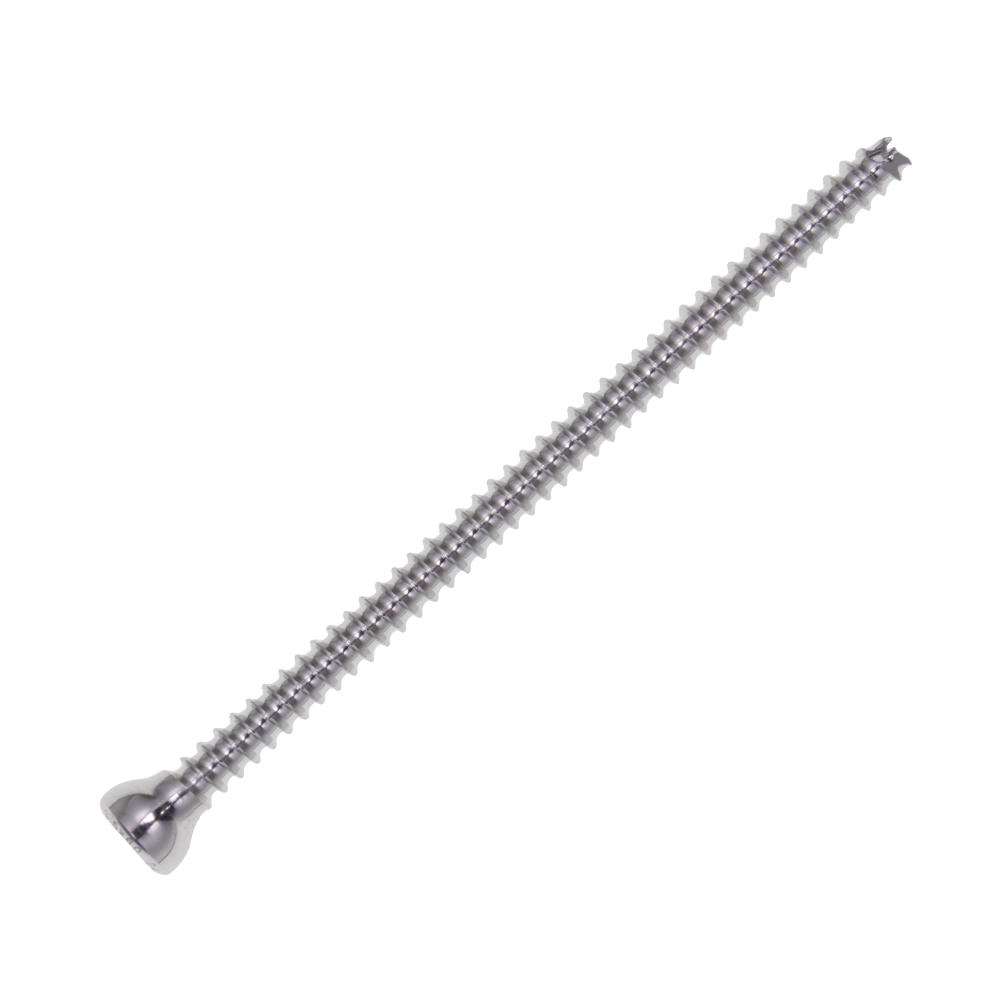

orthopedic implants screws

Orthopedic implant screws are essential medical devices designed to provide internal fixation and stability in bone fracture treatment and reconstructive surgery. These precision-engineered components, typically manufactured from biocompatible materials such as titanium or stainless steel, serve as crucial elements in modern orthopedic procedures. The screws come in various designs, including cortical, cancellous, and cannulated varieties, each specifically engineered for different bone densities and anatomical locations. Their unique threading patterns and precise dimensions ensure optimal bone purchase and stability during the healing process. Modern orthopedic implant screws incorporate advanced surface treatments and coatings that enhance osseointegration and reduce the risk of infection. The manufacturing process adheres to strict quality control standards, ensuring consistent performance and patient safety. These screws can be used in conjunction with plates, rods, and other fixation devices to create comprehensive treatment solutions for complex fractures and joint reconstructions. The versatility of orthopedic implant screws makes them indispensable in treating various conditions, from simple fractures to complex spinal fusion procedures.