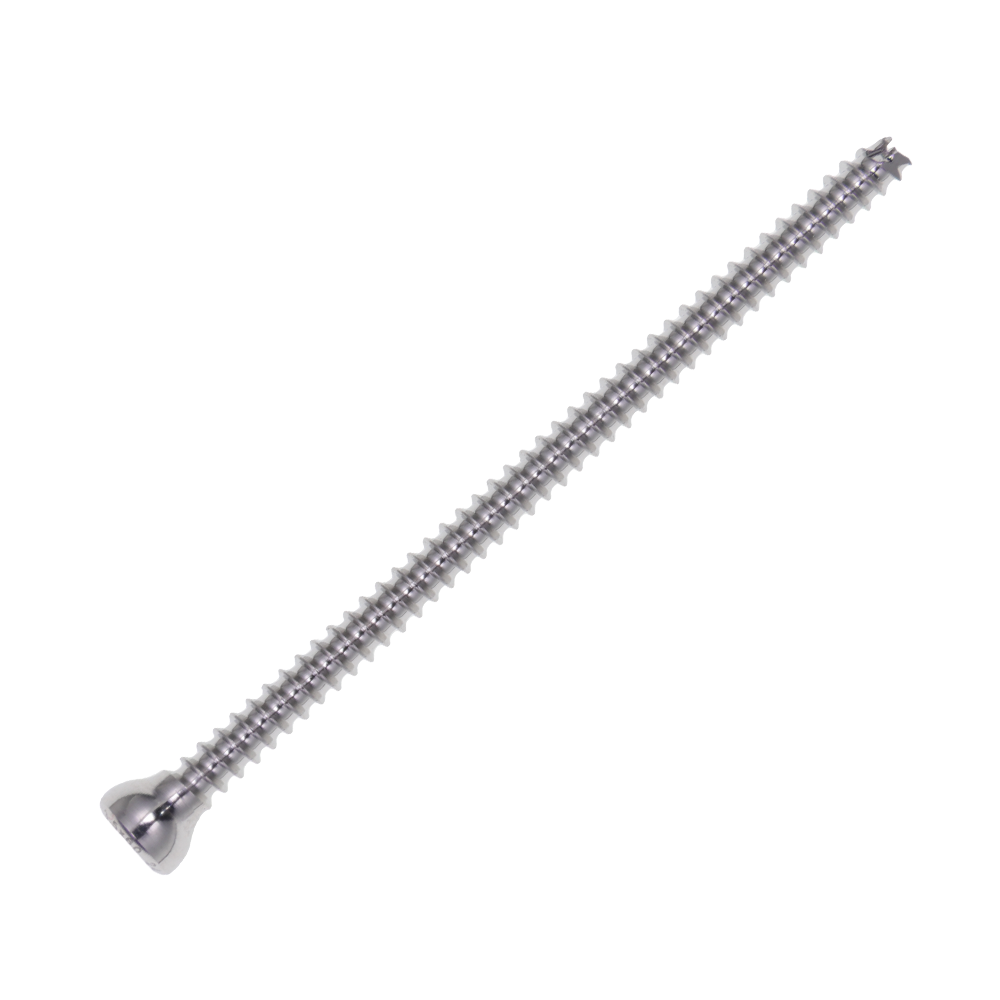

self tapping screw orthopedics

Self tapping screws in orthopedics represent a revolutionary advancement in surgical fixation technology. These specialized medical devices are engineered to create their own threading as they are inserted into bone, eliminating the need for pre-drilling in many applications. The screws feature a unique cutting flute design at the tip, which enables them to efficiently penetrate bone tissue while minimizing trauma to the surrounding area. Manufactured from biocompatible materials such as titanium alloys or stainless steel, these screws ensure optimal tissue response and long term stability. Their design incorporates precise threading patterns that enhance grip strength and promote better bone fixation, while their self drilling capabilities significantly reduce operating time and improve surgical efficiency. These screws are widely used in various orthopedic procedures, including fracture fixation, spinal fusion, and joint reconstruction. The technology behind these screws continues to evolve, with modern variants featuring specialized coatings that enhance osseointegration and reduce the risk of infection. Their versatility makes them suitable for both cortical and cancellous bone applications, while their mechanical properties ensure reliable fixation across different anatomical locations.