plates and screws used in orthopedic surgery

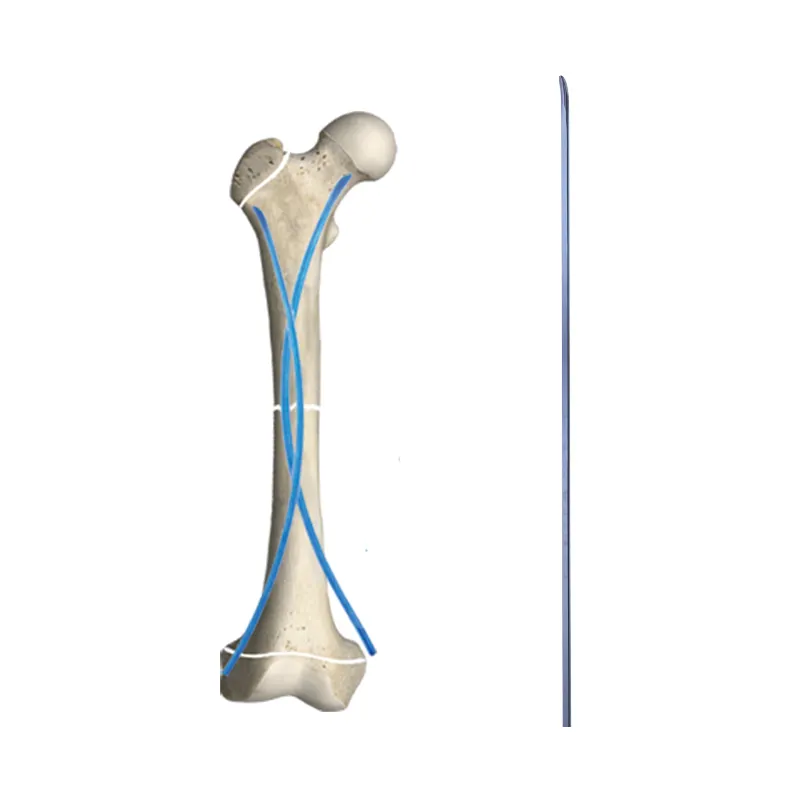

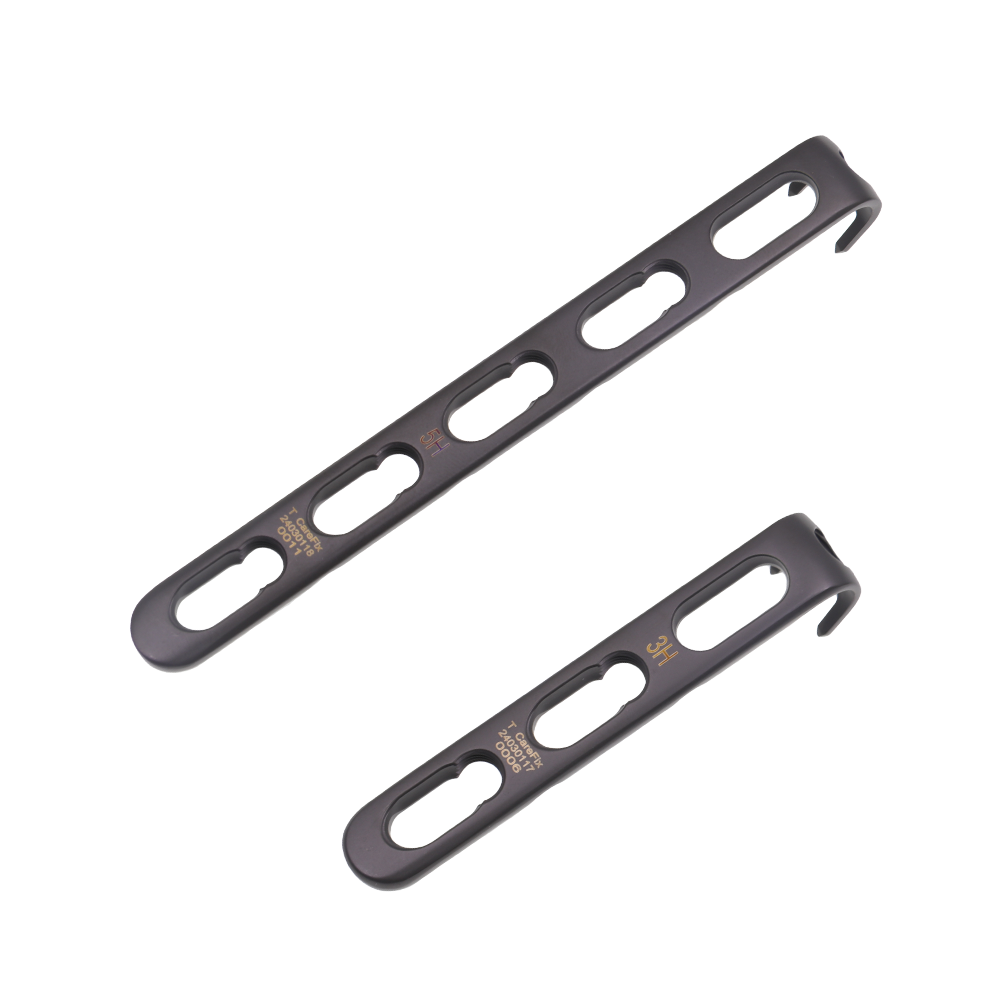

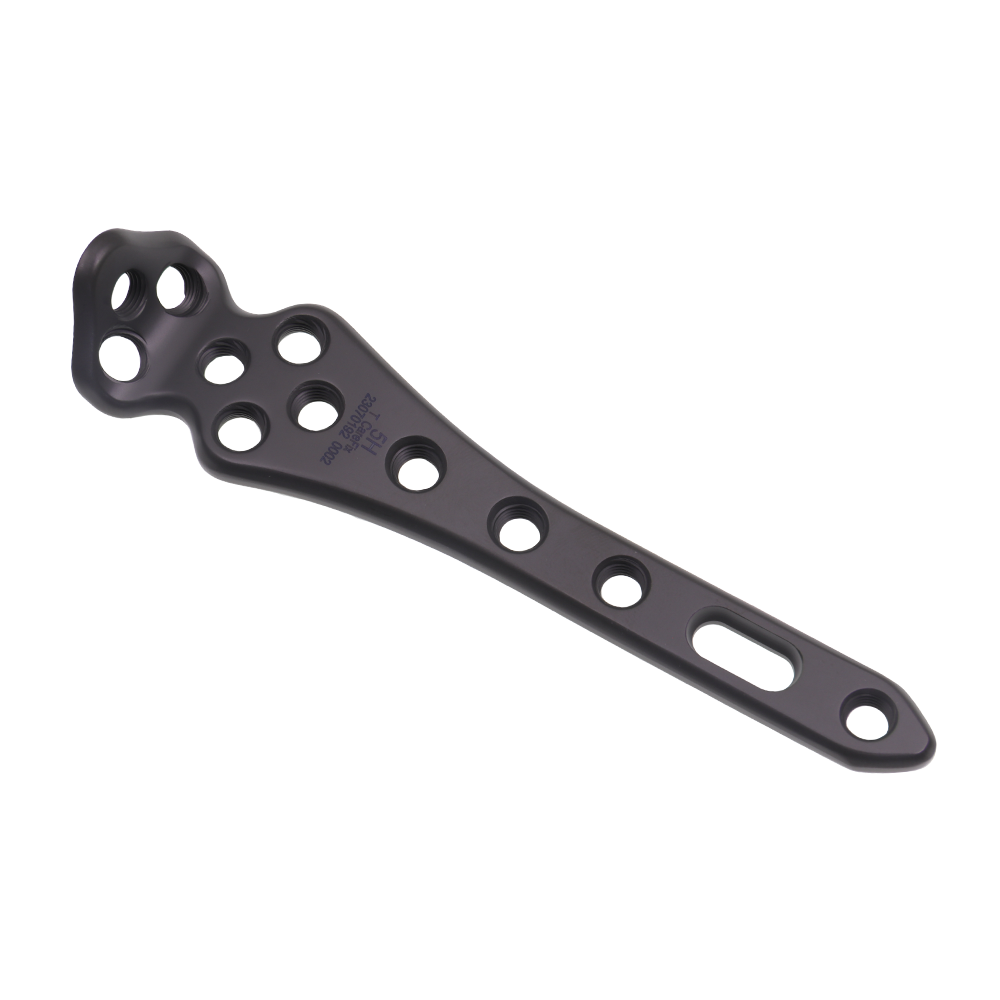

Orthopedic plates and screws represent essential components in modern surgical fixation systems, serving as crucial tools for stabilizing fractures and supporting bone healing. These medical devices are typically manufactured from biocompatible materials such as titanium alloys or stainless steel, engineered to provide optimal strength while maintaining compatibility with human tissue. The plates come in various shapes and sizes, designed to match different anatomical locations and fracture patterns. They feature precisely drilled holes that accommodate surgical screws, enabling surgeons to secure the plate firmly to the bone. Modern orthopedic plates incorporate advanced design elements such as low-contact profiles that minimize interference with blood supply to the bone, and locking mechanisms that create stable angular fixation. The screws used in conjunction with these plates are equally sophisticated, featuring specialized threading patterns and head designs that ensure secure fixation while preventing damage to surrounding tissue. Some systems include polyaxial locking mechanisms, allowing surgeons to insert screws at various angles while maintaining stable fixation. These implants undergo rigorous testing to ensure they meet strict biomechanical requirements and can withstand the forces encountered during normal patient activities. The technology continues to evolve with newer designs incorporating surface treatments that promote bone growth and reduce the risk of infection.