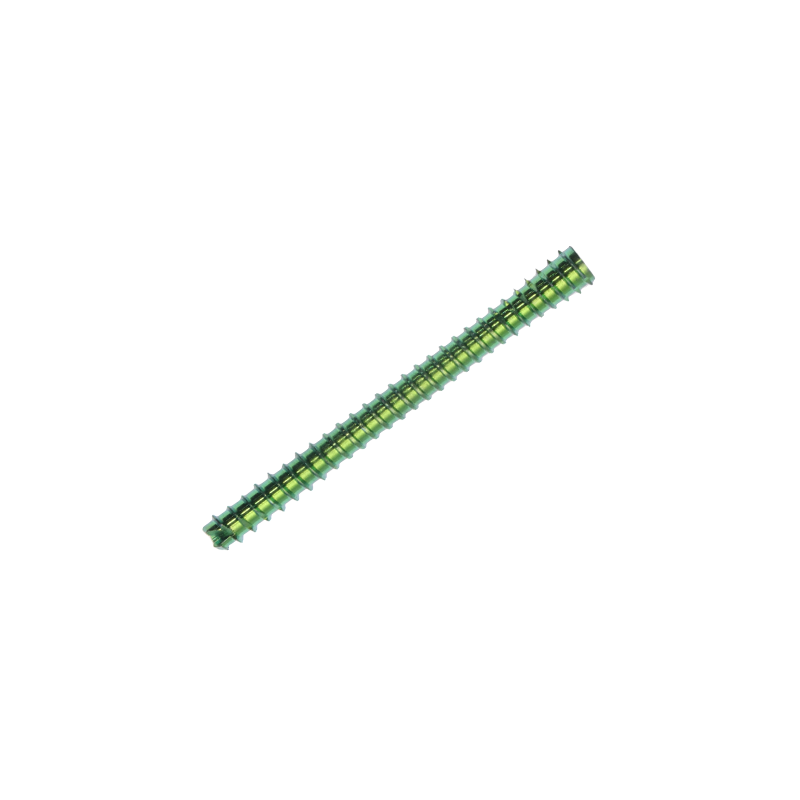

customized headless screw

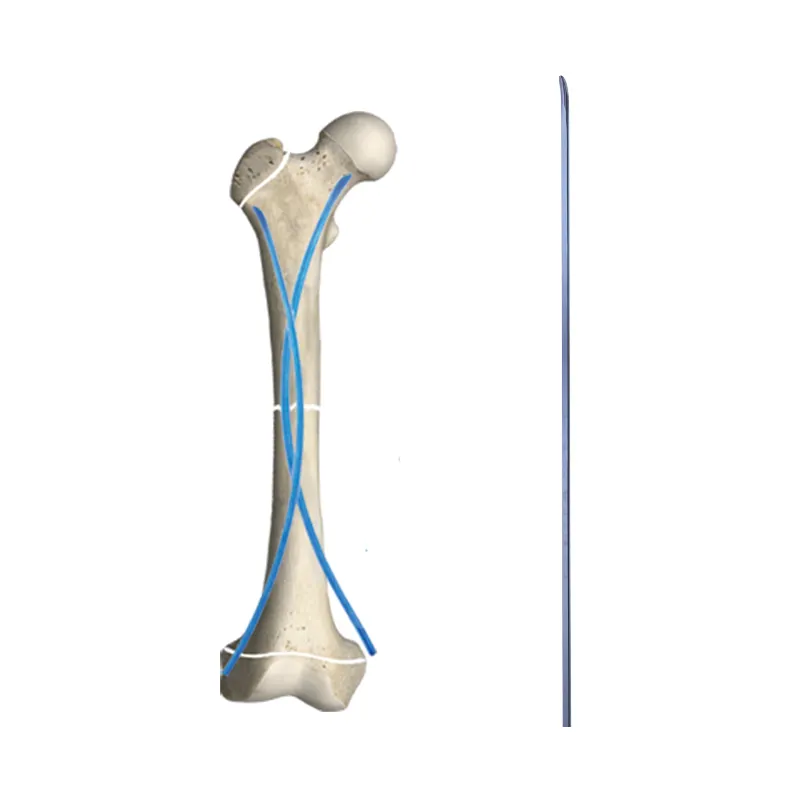

The customized headless screw represents a breakthrough in fastening technology, offering a sophisticated solution for applications where traditional screws fall short. These precision engineered components feature a unique design without a protruding head, allowing for seamless integration in flush mounting scenarios. Manufactured to exact specifications, these screws combine superior holding power with minimal visual impact, making them ideal for furniture assembly, architectural installations, and precision engineering projects. The customization options extend to thread pattern, length, diameter, and material composition, ensuring optimal performance across diverse applications. Advanced manufacturing processes ensure consistent quality and precise threading, while specialized coating options provide enhanced corrosion resistance and longevity. The screws exceptional versatility allows for both machine thread and wood thread variations, accommodating different material requirements and load bearing needs. Their design facilitates installation in confined spaces where conventional headed screws would be impractical, while maintaining robust mechanical properties for reliable performance.