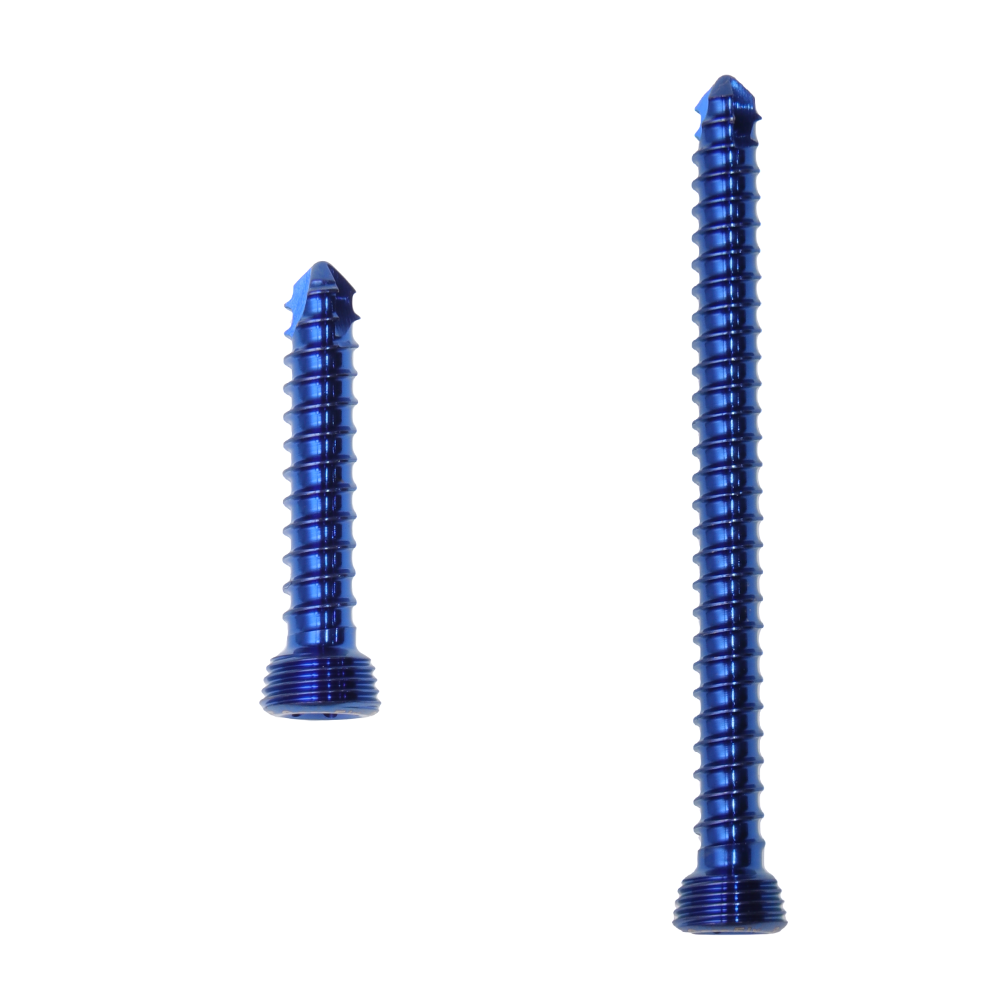

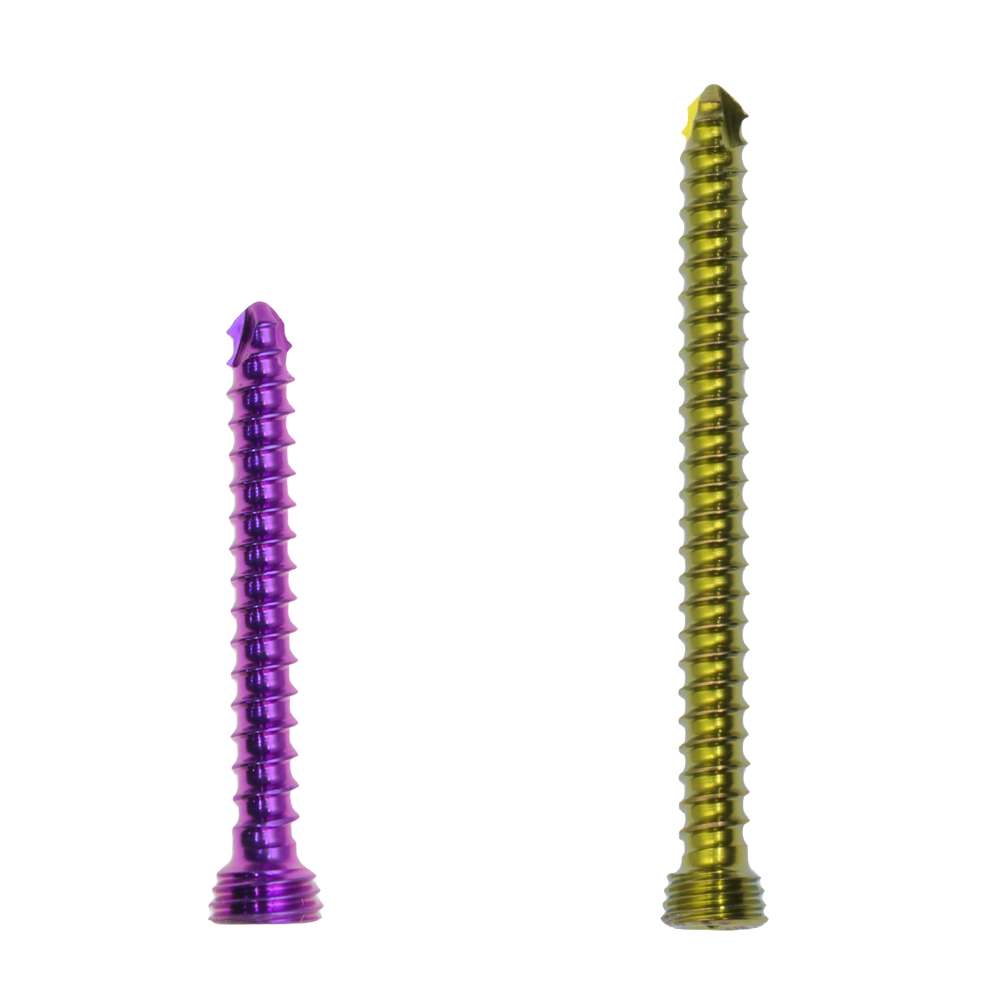

cortical locking screws

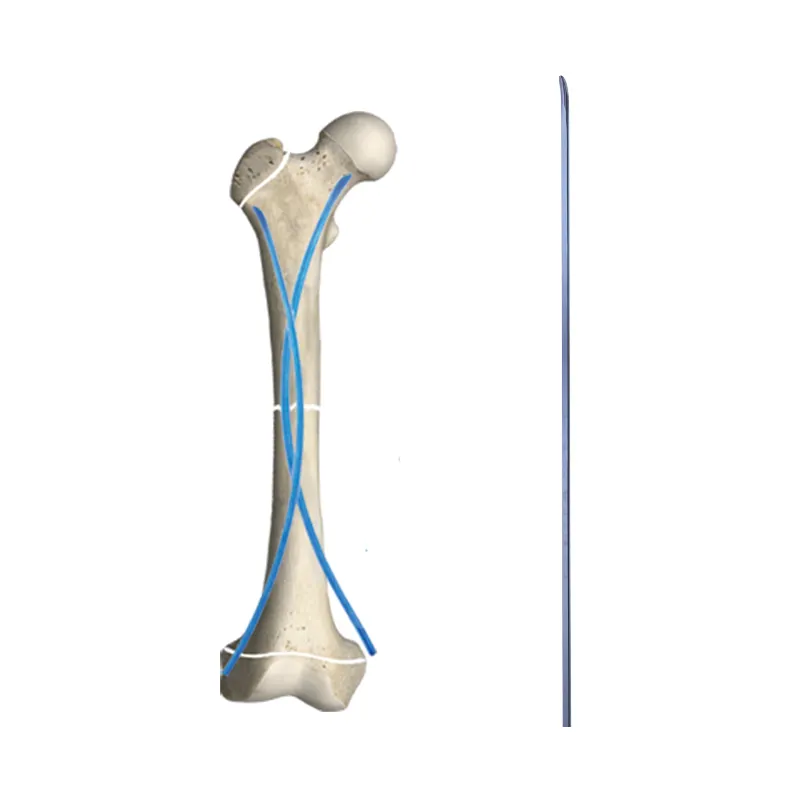

Cortical locking screws represent a significant advancement in orthopedic fixation technology, combining superior stability with enhanced healing outcomes. These innovative fasteners feature a unique threaded head design that locks securely into specially designed plates, creating a unified construct that provides exceptional stability for fracture fixation. The screws are manufactured from high-grade surgical stainless steel or titanium alloy, ensuring both durability and biocompatibility. When inserted, the threads on the screw head engage with corresponding threads in the plate holes, creating a fixed-angle construct that resists toggle and motion at the screw-plate interface. This locking mechanism distributes forces evenly across the entire plate length, reducing stress on individual screws and minimizing the risk of failure. The design particularly excels in osteoporotic bone, where traditional screws might have limited purchase. Cortical locking screws are available in various diameters and lengths to accommodate different anatomical requirements and fracture patterns. Their application spans across multiple orthopedic procedures, from complex fracture fixation to joint fusion surgeries, making them an indispensable tool in modern orthopedic surgery.