cannulated lag screw

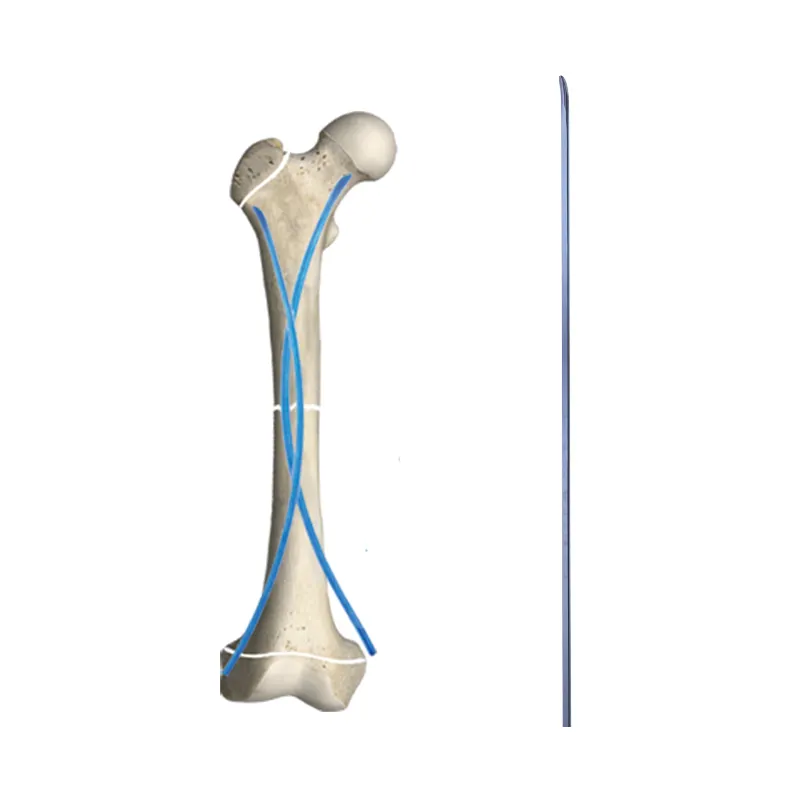

A cannulated lag screw represents a significant advancement in orthopedic fixation technology, combining precision with versatility in surgical applications. This specialized medical device features a hollow center channel running through its length, allowing for accurate placement using a guide wire. The design incorporates a wider thread diameter at the tip compared to the shaft, creating compression when tightened. The cannulated structure enables surgeons to perform minimally invasive procedures with enhanced accuracy and reduced operation time. These screws are manufactured from high-grade surgical stainless steel or titanium alloys, ensuring biocompatibility and durability. The threaded portion provides superior grip in bone tissue, while the smooth shaft allows for controlled compression across the fracture site. Available in various sizes and thread configurations, cannulated lag screws are particularly effective in treating fractures of the hip, ankle, and other weight-bearing joints. The innovative design allows for precise placement through small incisions, reducing trauma to surrounding tissues and promoting faster healing. Advanced coating technologies may be applied to enhance osseointegration and prevent infection, making these screws an essential tool in modern orthopedic surgery.