cannulated screw

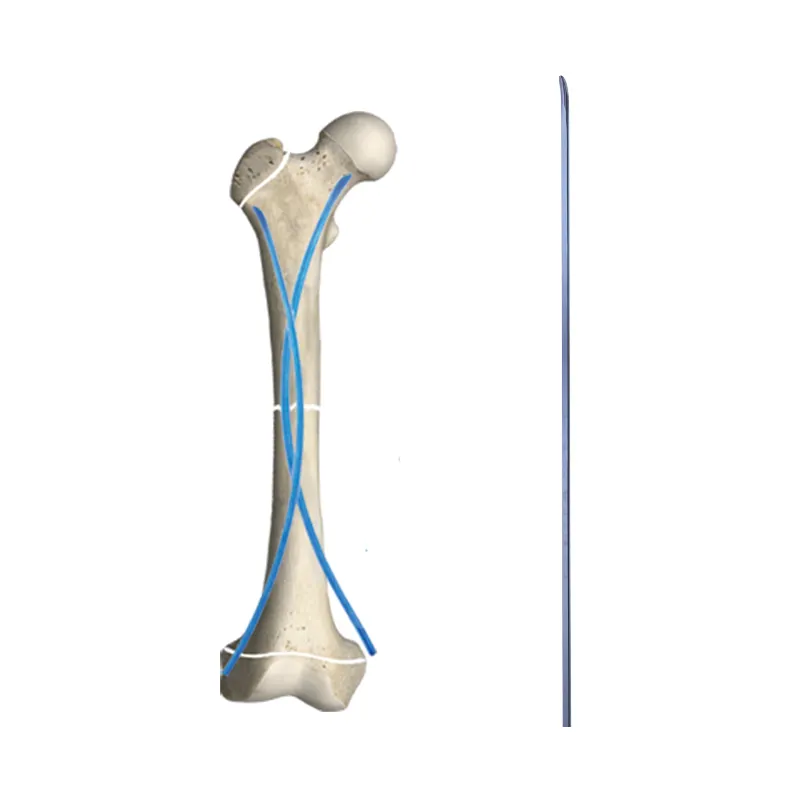

A cannulated screw is a specialized orthopedic implant designed with a hollow core running through its center, enabling precise placement through guidewire-assisted techniques. This innovative medical device combines superior mechanical strength with surgical versatility, making it an essential tool in modern orthopedic procedures. The hollow design allows surgeons to thread the screw over a pre-positioned guidewire, ensuring accurate placement and minimizing the risk of misalignment during insertion. Cannulated screws come in various sizes and thread patterns, accommodating different anatomical requirements and fracture patterns. The screws feature self-tapping threads that enhance fixation strength and facilitate easier insertion into bone tissue. Their design incorporates cutting flutes that reduce insertion torque and prevent bone damage during placement. The materials used in manufacturing cannulated screws, typically medical-grade stainless steel or titanium alloys, ensure biocompatibility and long-term stability. These screws are particularly valuable in treating fractures, arthrodesis procedures, and joint fusion operations, where precise positioning and strong fixation are crucial for successful outcomes. The technology behind cannulated screws continues to evolve, with newer designs incorporating advanced thread patterns and material compositions to enhance their performance and patient outcomes.