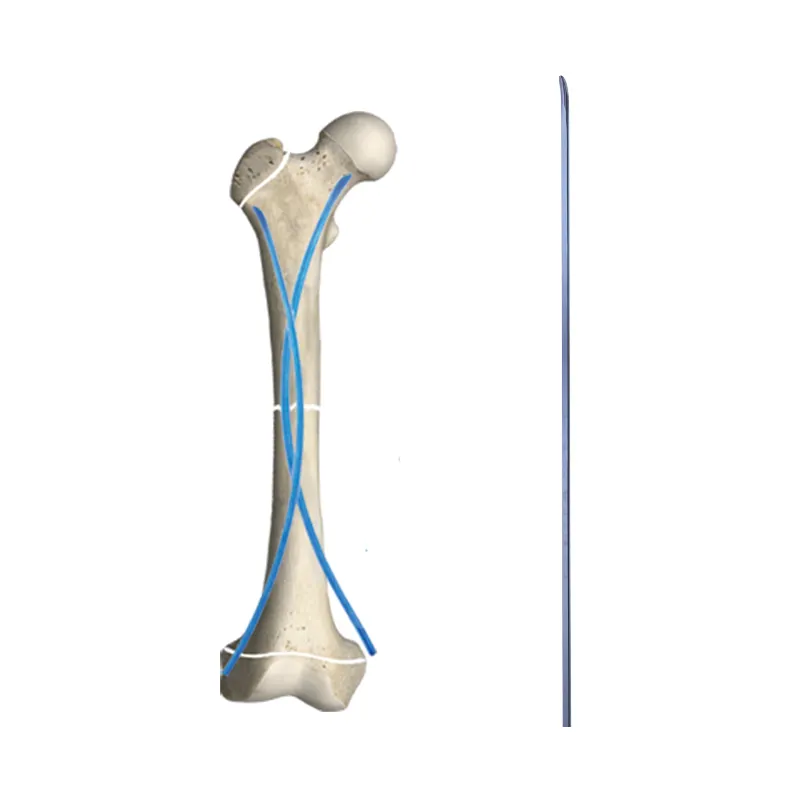

rush pin

A rush pin is a specialized fastening component designed for quick and secure assembly applications. This precision-engineered device combines durability with ease of use, featuring a spring-loaded mechanism that allows for rapid insertion and reliable retention. The rush pin's innovative design typically includes a retractable ball-lock system that engages automatically upon insertion, providing instant securing capability while maintaining the option for quick release when needed. Manufactured from high-grade materials such as stainless steel or hardened carbon steel, rush pins offer exceptional strength and corrosion resistance, making them suitable for diverse industrial applications. The design incorporates features such as knurled heads for improved grip, safety retention mechanisms to prevent accidental release, and size-specific tolerances for precise fit in various assembly scenarios. These pins are particularly valuable in applications where frequent assembly and disassembly are required, offering a tool-free solution that saves time and reduces maintenance complexity. Their versatility extends across multiple industries, from aerospace and automotive to manufacturing and military equipment, where reliable quick-release fastening is essential.