orthopedic surgery tools

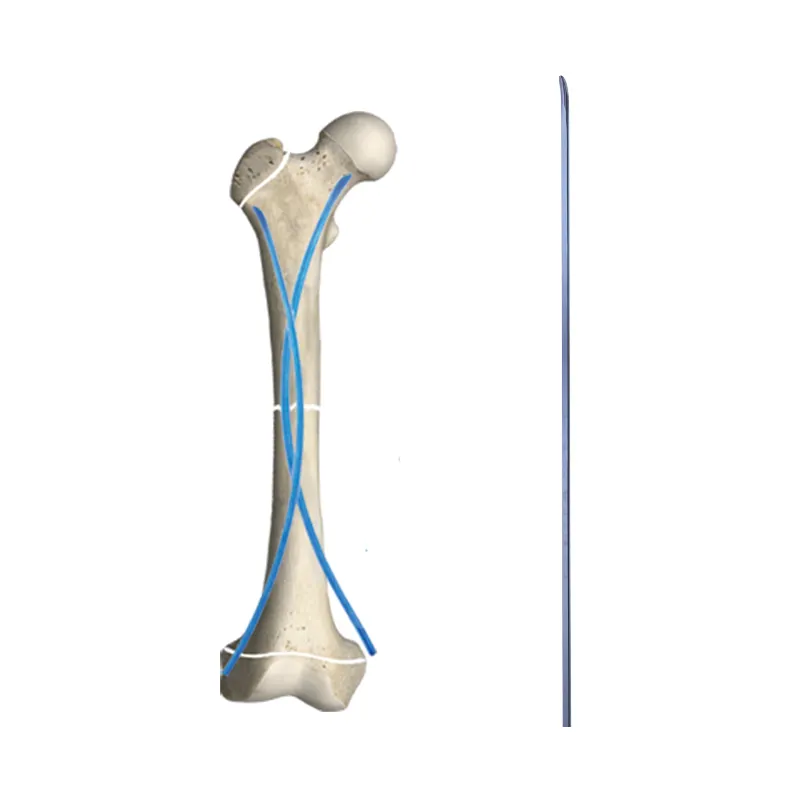

Orthopedic surgery tools represent a sophisticated array of precision instruments designed to facilitate complex musculoskeletal procedures. These specialized implements include power tools like surgical drills and saws, which enable surgeons to perform precise bone cuts and create pilot holes for implants. Manual instruments such as osteotomes, chisels, and various types of forceps provide essential control during delicate procedures. Modern orthopedic tools incorporate ergonomic designs and advanced materials like surgical-grade stainless steel and titanium alloys, ensuring durability and optimal performance. Many contemporary tools feature modular designs allowing for quick assembly and sterilization. Digital integration has introduced smart tools with sensors that provide real-time feedback on positioning and pressure application. The toolset includes specialized instruments for joint replacement procedures, trauma surgery, and minimally invasive techniques. Measurement devices and alignment guides ensure precise implant positioning and surgical accuracy. These tools undergo rigorous quality control and sterilization processes to maintain the highest standards of patient safety and surgical outcomes.