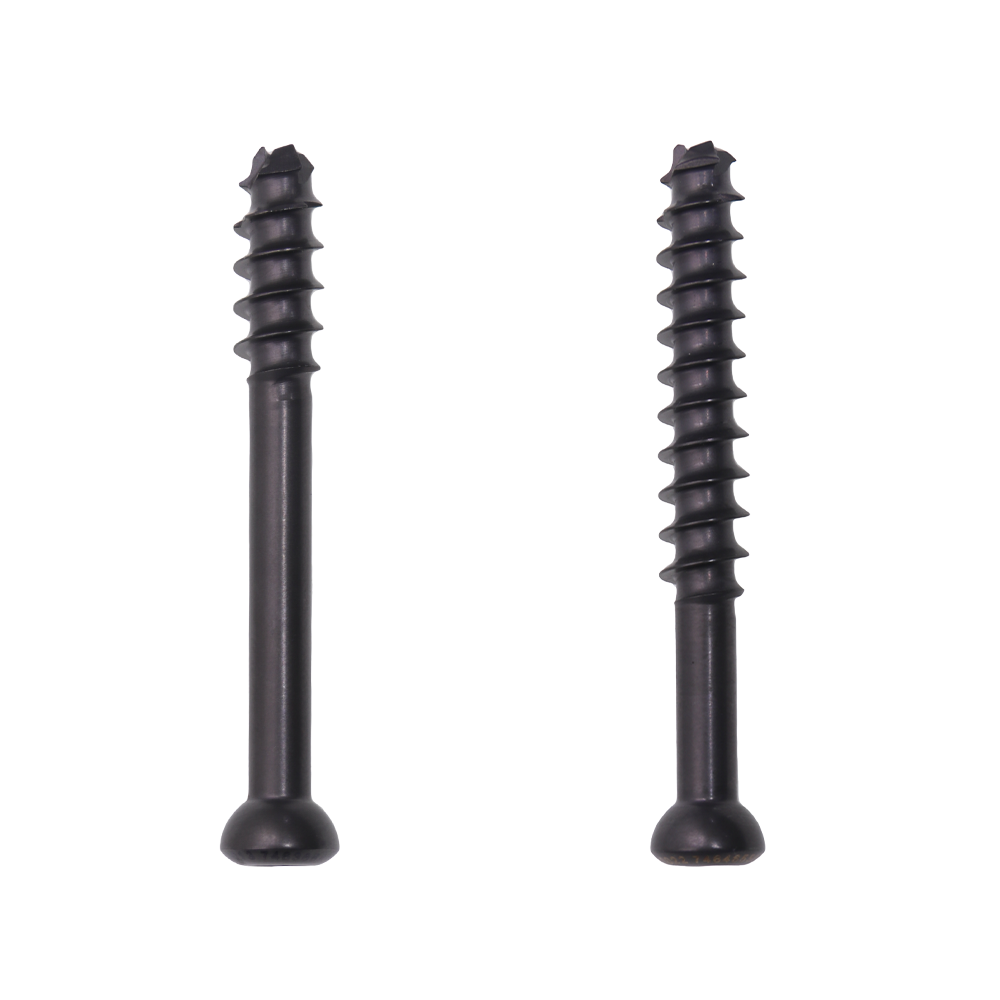

customizable orthopedic screws

Customizable orthopedic screws represent a significant advancement in modern orthopedic surgery, offering surgeons unprecedented flexibility and precision in treating various bone-related conditions. These innovative medical devices are engineered with patient-specific requirements in mind, featuring adjustable thread patterns, lengths, and diameters to accommodate different anatomical structures and bone densities. The screws are manufactured using high-grade biocompatible materials, typically titanium alloys or stainless steel, ensuring optimal integration with surrounding tissue and long-term stability. Advanced manufacturing techniques, including 3D printing and precision machining, enable the production of screws with exact specifications matching individual patient needs. The customization options extend to thread design, head configuration, and coating materials, allowing surgeons to select the most appropriate combination for specific surgical procedures. These screws find applications across various orthopedic procedures, including spinal fusion, fracture fixation, joint reconstruction, and trauma surgery. The ability to customize these components has significantly improved surgical outcomes by providing better mechanical stability and reducing the risk of complications.