im nail manufacturer

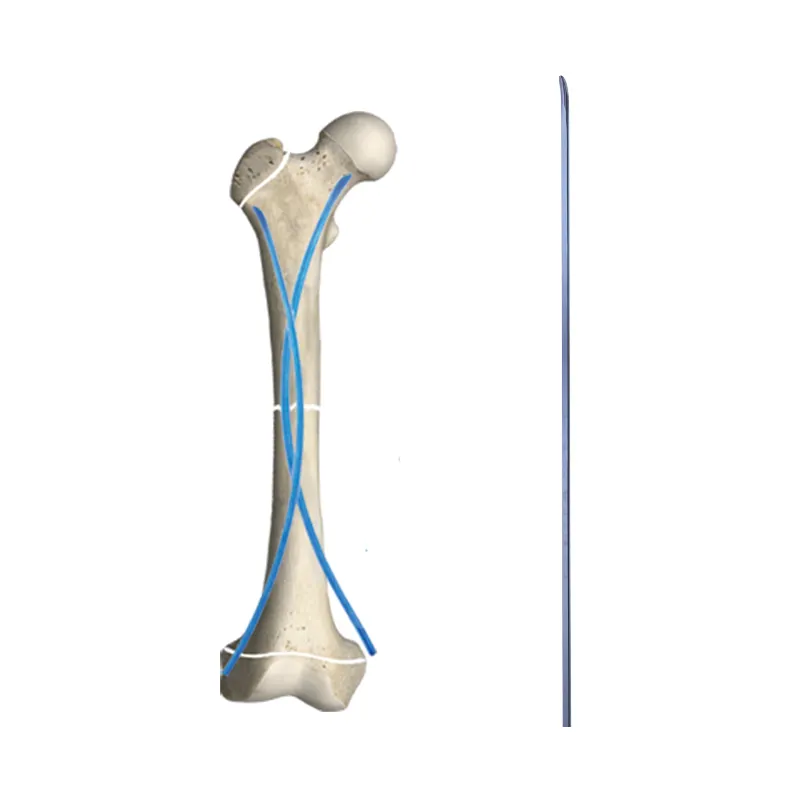

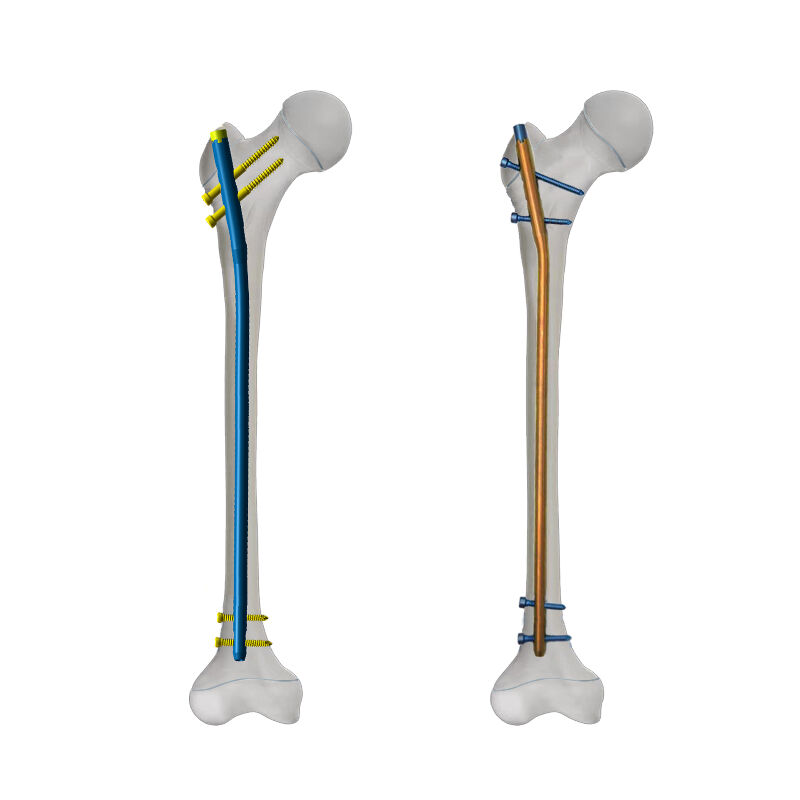

The IM nail manufacturer represents a cutting-edge solution in orthopedic medical device production, specializing in the development and manufacturing of intramedullary nails used in fracture fixation procedures. With state-of-the-art manufacturing facilities equipped with precision CNC machinery and advanced quality control systems, the manufacturer ensures consistent production of high-quality IM nails that meet international standards. The facility incorporates automated production lines that maintain strict tolerances and surface finish requirements, essential for medical-grade implants. The manufacturer utilizes medical-grade titanium and stainless steel materials, processed under ISO 13485-certified conditions to ensure biocompatibility and structural integrity. Their comprehensive product range includes nails for femoral, tibial, and humeral applications, with various diameters and lengths to accommodate different patient anatomies. The facility's integrated research and development department continuously works on innovative designs, incorporating feedback from surgeons and healthcare professionals to enhance product functionality and ease of use. Quality assurance protocols include rigorous testing procedures, from material verification to final product inspection, ensuring each IM nail meets the highest standards of safety and reliability.