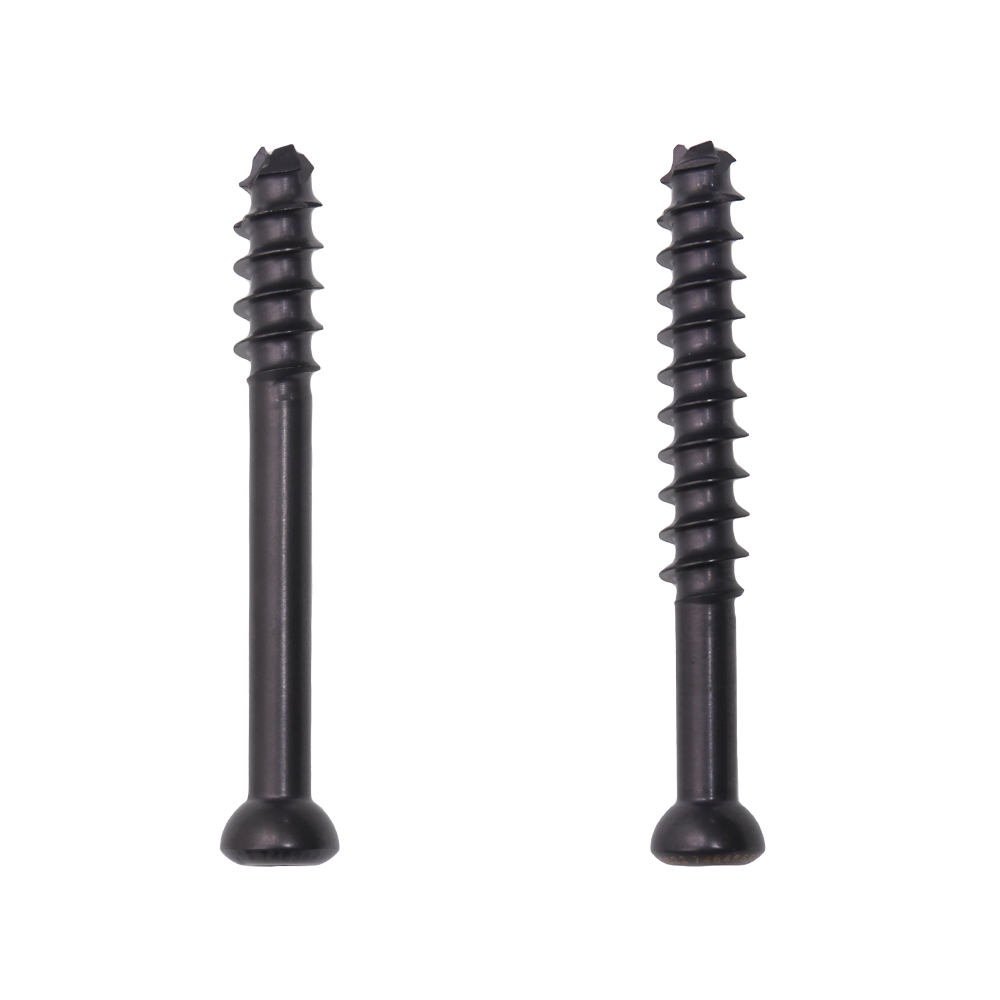

self tapping screws orthopedics

Self tapping screws in orthopedics represent a revolutionary advancement in surgical fixation technology. These specialized medical devices are engineered to create their own threading as they are inserted into bone, eliminating the need for pre drilling in many applications. The screws feature precision engineered threads and cutting flutes that efficiently remove bone material while maintaining structural integrity. They are commonly manufactured from biocompatible materials such as titanium or stainless steel, ensuring long term stability and patient safety. The design incorporates various thread patterns and dimensions to accommodate different bone densities and anatomical locations. These screws are particularly valuable in trauma surgery, spinal procedures, and reconstructive orthopedics, offering surgeons enhanced control and efficiency during placement. The self tapping mechanism significantly reduces operative time and minimizes bone trauma compared to traditional screwing methods. Advanced coating technologies may be applied to enhance osseointegration and prevent infection. The screws are available in multiple diameters and lengths, allowing surgeons to select the optimal size for specific clinical applications.